Melt Blown Yoven What Machira

Melt Blown Yoven What Machira

Kuongorora

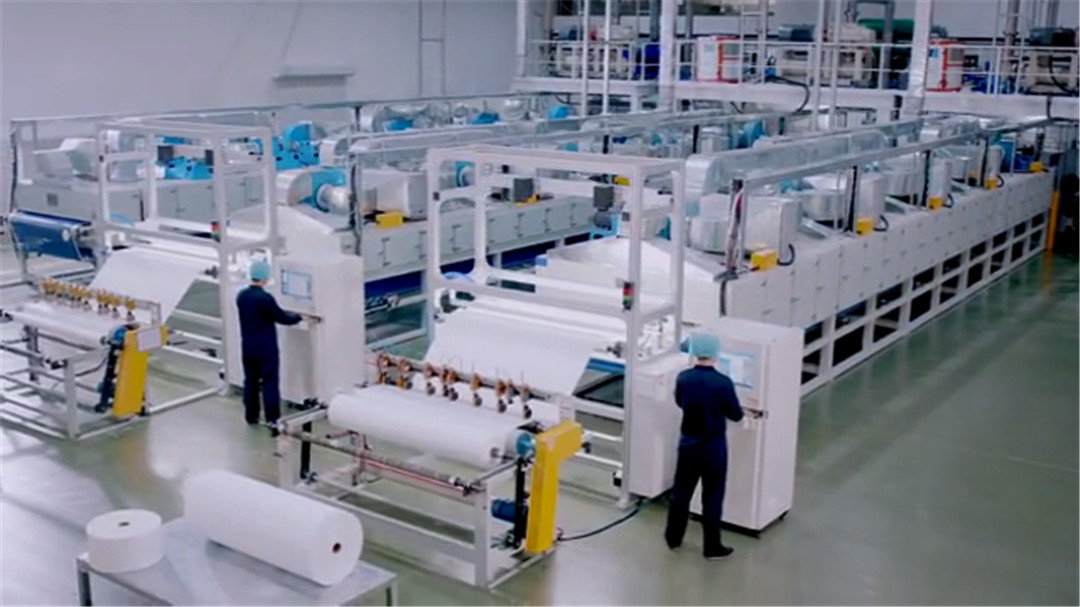

Meltblown isina kuchena inoumbwa kubva pane yekunyungudika iyo inowedzera uye inodhonza moliffastic inofa nemhepo yakakwira kune iyo Superity Filing Iyo mafaira ari muyamende yebhuroka yakaunganidzwa pamwe chete nekusanganiswa kwekunakirwa uye kubatanidza kunamatira.

Iyo Meltblown isina kuchena machira inonyanya kugadzirwa ne polypropylene resin. Iyo inonyungudika inovharidzira machira akanaka uye anowanzo kuyerwa mumakroni. Yayo dhayamita inogona kuve 1 kusvika ku5 micons. Kuve neyako Ultra-yakanaka fiber chimiro chinowedzera nzvimbo yayo inowedzera nzvimbo yayo uye huwandu hwenzvimbo yeyunivhesiti, inouya nekuita kwekunakisa muFiltration, kuzvidzivirira, kupisa kwezvinhu uye zvemafuta zvekushandisa uye zvemafuta.

Iko kunoshandiswa kukuru kweyamonyaniswa-kwakapepetwa nonwovens uye dzimwe nzira dzekunyepedzera dzakatevera.

Filt

Nonwoven inonyungudika-blown machira ari porous. Nekuda kweizvozvo, ivo vanogona kushata zvinwiwa nemagasi. Maoko avo anosanganisira kurapwa kwemvura, masks, uye mafirita ekuratidzira emhepo.

Norbents

Zvinhu zvisina ruzivo zvinogona kuchengetedza zvinwiwa kakawanda uremu hwavo. Saka, avo vakagadzirwa kubva kuPolypropylene vakanakira kuunganidza mafuta kusvibiswa. Iyo yakanyanya kuzivikanwa application ndeyekushandiswa kwehuremu kuti utore mafuta kubva pamusoro pemvura, sekusangana mumvura ine tsaona.

Hurgiene zvigadzirwa

Iko kukwira kwakanyanya kwekunyungudika-blown machira anodzvanywa mumakwenzi ekurasa magwaro, kusakwana kwevanhu vakuru kuyamwisa zvigadzirwa, uye zvigadzirwa zvechikadzi hygiene.

Zvipfeko

Manyiriri-akaridzwa-blown machira ane hunhu hutatu hunobatsira kuvaite kuti vabatsire zvipfeko, kunyanya munzvimbo dzine hutsinye: kupokana kwekunhuhwirira, kupokana kwakasimba uye kudzvanywa.

Dhirowa Dhirowa

Melt kuputika kunogona kuburitsa zvinodhaka-zvinodhaka maficha ekudzora zvinodhaka. Iyo yakakwira inodhaka yekuuraya

Electronic Specialties

Zvishoma zvikumbiro zvakakura zviripo mumagetsi mashura emusika weMelt Blown Webs. Imwe yakafanana nemucheka wechiLiner mune komputa floppy disks uye imwe sevaparidzi vaparadzanisi uye seyakajeka mumapoka.