100% Original Melt Blown Fabric Layer - Oil-absorbing Non Woven Materials – Medlong

100% Original Melt Blown Fabric Layer - Oil-absorbing Non Woven Materials – Medlong Detail:

Oil-absorbing Materials

Overview

The methods to deal with oil pollution in the water bodies mainly include chemical methods and physical methods. The chemical method is simple and the cost is low, but it will produce a large number of chemical runoff, which will have an adverse impact on the ecological environment, and the scope of application will be limited to a certain extent. The physical method of using a melt-blown cloth to deal with oil pollution of the water bodies is more scientific and widely used.

Polypropylene melt-blown material has the chemical properties of good lipophilicity, poor hygroscopicity, and insoluble in oil and strong acid and alkali. It is a new type of oil-absorbing material with high efficiency and no pollution. Lightweight, after oil absorption, it can still float on the water surface for a long time without deformation; it is a non-polar material, by adjusting the product weight, fiber thickness, temperature, and other technological processes, the oil absorption ratio can reach 12-15 times its own weight.; non-toxic, good water and oil replacement, can be used repeatedly; by burning method, The processing of polypropylene melt-blown cloth does not produce toxic gas, can burn completely and release a lot of heat, and only 0.02% of ash remains.

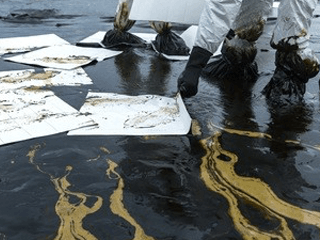

Melt-blown technology plays a vital role in cleanup efforts and slowing the spread of a massive oil spill. At present, polypropylene melt-blown oil-absorbing materials are widely used in environmental protection and oil-water separation projects, as well as in the field of marine oil spills.

Medlong Nonwoven fabric is created by our advanced melt-blown technology, and made of brand new polypropylene, creating a low-linting but high absorbency fabric. It has good performance for both liquids and oil cleaning jobs.

Functions & Properties

- Lipophilic and hydrophobic

- High oil retention rate

- Good thermal stability

- Reusable performance

- Oil absorbent performance and structural stability

- Large saturated oil absorption

Applications

- Heavy-duty cleaning

- Remove Stubborn Stains

- Hard surface Cleaning

Because of the microporosity and hydrophobicity of its fabric, it is an ideal material for oil absorption, the oil absorption can reach dozens of times its own weight, the oil absorption speed is fast, and it does not deform for a long time after oil absorption. It has good water and oil replacement performance, can be reused, and stored for a long time.

It is widely used as absorbing material for equipment oil spill treatment, marine environmental protection, sewage treatment, and other oil spill pollution treatment. At present, there are also specific laws and regulations that require ships and ports to be equipped with a certain amount of melt-blown non-woven oil-absorbing materials to prevent oil spills and deal with them in time to avoid environmental pollution. It is usually used in oil-absorbing pads, oil-absorbing grids, oil-absorbing tapes, and other products, and even household oil-absorbing products are gradually being promoted.

Product detail pictures:

Related Product Guide:

With a sound enterprise credit history, exceptional after-sales services and modern production facilities, we've earned an outstanding track record amongst our consumers across the whole world for 100% Original Melt Blown Fabric Layer - Oil-absorbing Non Woven Materials – Medlong, The product will supply to all over the world, such as: Miami , Angola , Spain , We'll initiate the second phase of our development strategy. Our company regards reasonable prices, efficient production time and good after-sales service as our tenet. If you are interested in any of our products and solutions or would like to discuss a custom order, make sure you feel free to contact us. We've been looking forward to forming successful business relationships with new clients around the world in the near future.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.